Anodes and electrodes for electroplating

Products & Processes

Apparatus engineering lead / steel

Anodes and electrodes for electroplating

Anodes for galvanic processes

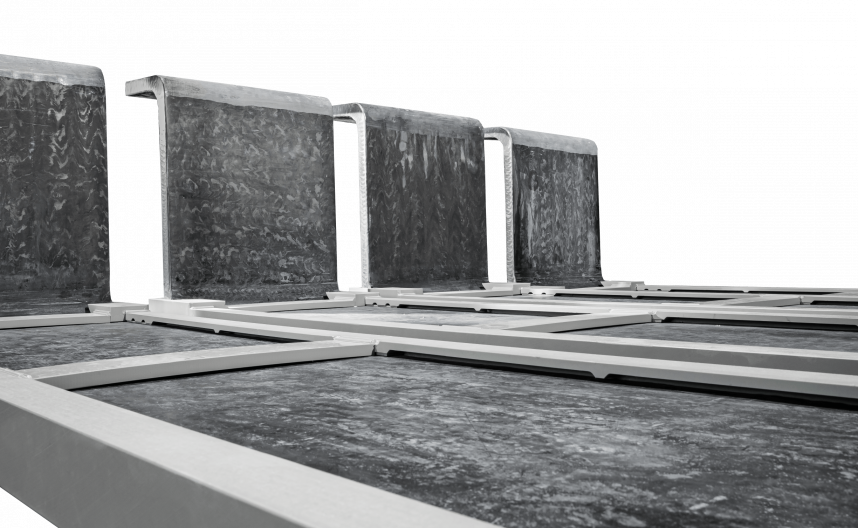

One of JL Goslar's specialities is the production of lead lined anodes for stainless steel pickling lines. Stainless steel strips are further treated in continuous annealing and pickling lines after cold working. Annealing represents a refinement, but at the same time an essential heat treatment. Oxides, scale and heat discolouration must be treated and removed by pickling. In this process, the steel strip is passed between current-carrying anode and cathode pairs and the shine and corrosion resistance of the stainless steel is improved. Using special lead alloys, we produce extremely durable anodes with high economic efficiency. The results are satisfied customers worldwide.