Nuclear Technology

Products & Processes

Radiation Protection & Engineering

Nuclear Technology

For nuclear technology, JL Goslar supplies every type of shielding (e.g. transport containers, hazardous goods containers, radiation protection cabins, lead chambers, hot cells, lead mats) and an extensive range of technical semi-finished products (e.g. rolled lead, lead profiles) and radiation protection materials.

As the world's leading manufacturer of tank containers for radioactive liquids and as an exclusive partner, we supply the nuclear industry with special containers for the transport of radioactive liquids. Our containers comply with the highest international safety guidelines and are approved for rail and road transport for hazardous material class 7 according to ADR/RID.

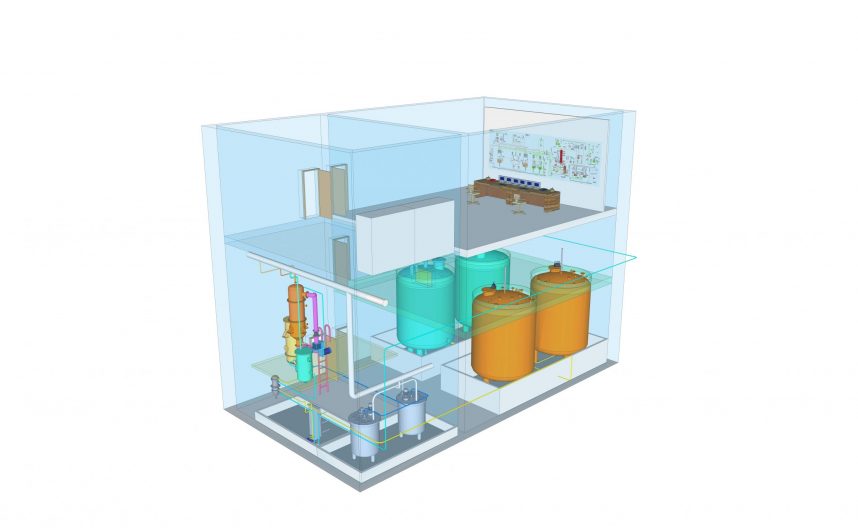

We adapt the filling systems to the different plant systems. For PLC-controlled filling, there are the variants vacuum/compressed air or pump systems. The electronic control is integrated in the container.

The container equipment is individually adapted to the individual requirements. For example, it includes vacuum pumps, compressors or exhaust air filters on-board. Additional collecting trays for condensate supplement the container frame construction. Tank container and fairing are coated with decontamination paint. The design of the ISO tank container frame allows transport on commercially available chassis. If required, we can also supply specially adapted transport trailers.

Depending on the requirements of the intended cargo, the high security tank is equipped with a double-walled shell or a steel-lead sandwich shell and can be designed with or without plastic coating. The wall construction and the thickness of the shielding depend on the cargo to be transported. On request, the tank can be equipped with an automatic control concept and/or a leak detection system. Service and maintenance work can be carried out on the container's accessible platform. The control concept makes automatic closure of the tank valves possible in the event of malfunctions.

Lead castings

Self-produced or provided double-walled shields (e.g. transport containers, radiation source shields, protection shields) made of black or stainless steel, copper or aluminium are cast without pores and cavities using a special process (MSC) developed by us.

Special lead castings are used to shield X-rays, measuring instruments and piping parts. The materials used are metallurgical lead, hard lead or low-radiation lead.