Plants and equipment for chemistry and metallurgy

Products & Processes

Apparatus engineering lead / steel

Plants for chemistry and metallurgy

Equipment manufacturing for the chemical and electroplating industries

Lead has been a proven material in chemical apparatus engineering for many decades. Due to its high corrosion resistance to numerous inorganic media, it is used in pressure vessels, autoclaves, and process vessels, among other things.

Homogeneous lead lining creates a metallurgical bond between the steel base material and the lead. It combines the mechanical load-bearing capacity of steel with the corrosion protection of lead. This process is used in particular where temperature, pressure, or vacuum requirements make pure lead sheet lining technically or economically unfeasible.

Automated homogeneous lead-lining, which has been in use since 1972 and has undergone continuous development, enables the economical production of even large-scale equipment for industrial use.

Manufacturing parameters:

• Diameter up to 5.6 m

• Individual weights up to 130 t

Large-volume containers and apparatus in homogeneous designs can also be produced on construction sites.

Execution and testing are carried out in accordance with DIN 28058. Design, calculation, material selection, and CAD layout are carried out taking into account the respective mechanical, thermal, and chemical stresses.

Experienced specialists prepare expert inspection reports as a basis for maintenance and preservation planning.

In addition, JL Goslar carries out repairs, refurbishments, and general overhauls of equipment and filter systems—worldwide, close to the process, and on both its own and third-party systems. This applies to both chemical and metallurgical plants.

Homogeneous lead-lined wet electrostatic precipitators (WESPs) are used worldwide in chemical and metallurgical plants. Thanks to their mechanical stability and high corrosion resistance, these systems achieve long service lives—depending on process conditions, design, and maintenance.

Insbesondere bei nasskatalytischen Verfahren sowie bei Belastungen durch Schwefelsäureaerosole (H₂SO₄) werden Elektrofilter aus Blei oder Blei-Kunststoff-Verbundwerkstoffen eingesetzt. Sie leisten einen wesentlichen Beitrag zur Reduzierung von Emissionen und zur Einhaltung geltender Umweltanforderungen.

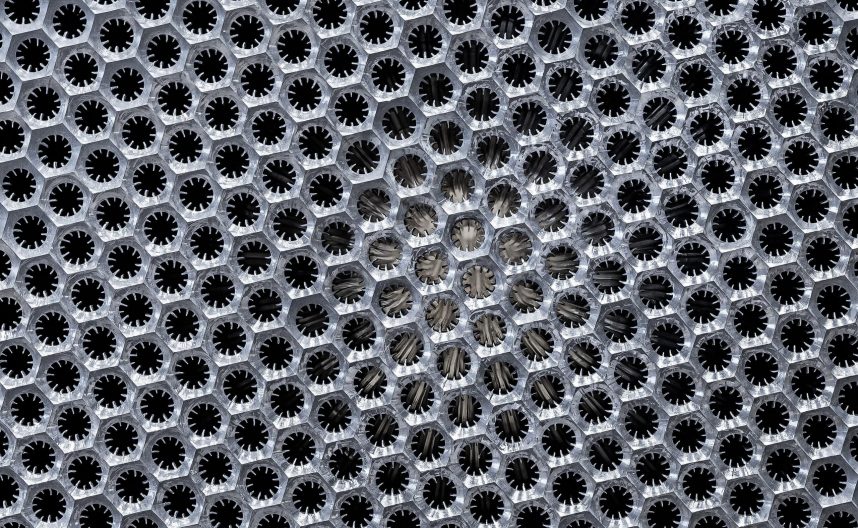

Precipitation system and emission electrodes

JL Goslar manufactures precipitation systems for new construction, spare parts supply, and revamping of existing wet electrostatic precipitators. The scope of services includes:

• Platten, rund und Quadratrohrsysteme

• Special geometries, e.g., octagonal cross-sections

The emission electrodes (spray electrodes) are specifically adapted to the respective precipitation system and the process requirements in terms of shape, dimensions, and material.

To avoid the operational disadvantages of conventional oil insulation, dry insulation for wet electrostatic precipitators was developed. This is used worldwide and offers the following advantages, among others:

• No insulating oil in the high-voltage range

• Reduced maintenance requirements

• Lower risk of oil spills or contamination

Dry insulation increases operational safety and simplifies maintenance of wet electrostatic precipitator systems.

For many decades, JL Goslar has been manufacturing star tube coolers as components of gas cleaning and process gas systems. Among other things, they are used in sulfuric acid production to cool process gases, condense water from the gas, and achieve defined operating conditions.

Star tube coolers are heat exchangers made of lead, a material with high resistance to weak and medium-strength acids.

To improve heat transfer, the lead pipes are equipped with internal ribs. The pipes required for this, with a star-shaped internal profile, are manufactured at JL Goslar on an extruder press.

The number of star tubes and the height of the coolers are designed specifically for each process. After production, a pressure test is carried out in accordance with the applicable technical regulations.

Many years of operational experience confirm high reliability and a long service life. At the end of its life cycle, the materials used are recyclable, supporting the sustainable use of lead.