Plants for chemistry and metallurgy

Products & Processes

Apparatus engineering lead / steel

Plants for chemistry and metallurgy

Plants for chemistry and metallurgy

Apparatus for the chemical and electroplating industry

Lead has proven itself in chemical apparatus engineering due to its physical and chemical properties, especially in corrosion protection, and is therefore used, among other things, for the production of pressure autoclaves. As a composite material, homogeneous lead combines the strength of steel with the excellent corrosion resistance of lead. It is used wherever high temperatures, pressure or negative pressure do not permit a lead sheet lining. Automated homogeneous lead lining, which was introduced in 1972 and has been continuously further developed, enables the economical production of corrosion-protected large apparatus.

We manufacture components up to a diameter of 5.6 metres with unit weights of up to 130 tonnes. In addition, we also manufacture containers of any size in homogeneous design within the scope of construction site production. Homogeneous lead coating is carried out and tested in accordance with DIN 28058. Necessary calculations, the correct choice of materials and CAD designs are carried out professionally, taking into account all stresses caused by mechanical and chemical loads.

Inspection, repair and general overhaul of old systems Experienced and knowledgeable specialists prepare well-founded inspection reports for your maintenance planning and carry out repairs and general overhauls of apparatus and filter systems worldwide.

Wet electrostatic precipitator

Homogeneous leaded filter systems are used in metallurgical and chemical plants worldwide. Due to their excellent mechanical stability and corrosion resistance, our filters have been operating successfully in many plants for over 25 years without the need for repairs. Especially for wet catalytic processes and high loads of sulphuric acid aerosols, electrostatic precipitators made of lead or lead and conductive plastics are also used to reduce H2SO4 emissions. Emissions can thus be reduced below the detection limit.

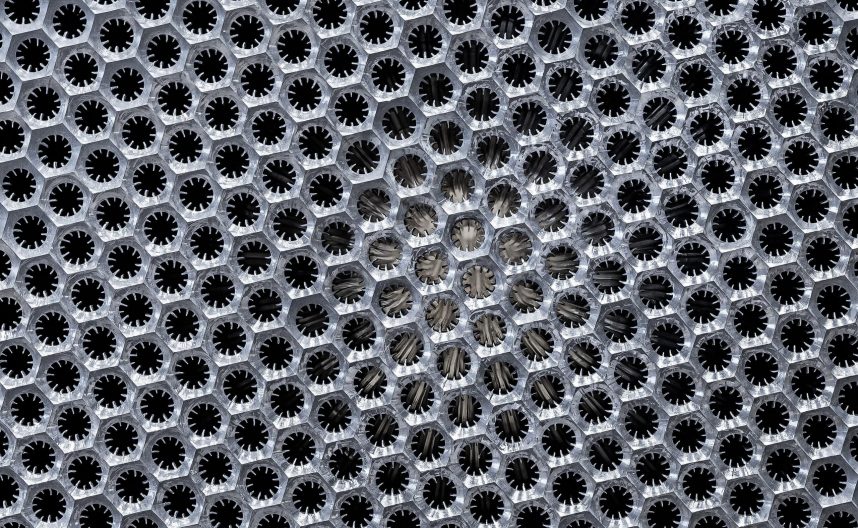

Precipitation system and emission electrodes

Due to consistent further development over the past years, we now manufacture all types of precipitation systems that can be used as spare parts or for revamping existing systems. From conventional plate filters to round and square tube profiles to our own developed octagonal cross-section. We adapt the shape and size of the emission electrodes (spray electrodes) to the different precipitation systems and customer requirements.

Dry insulation

To overcome all the disadvantages of the oil insulation of wet electrostatic precipitators, we have developed the dry insulation. This dry insulation is used worldwide and offers significant advantages. The dry insulation is practically maintenance-free, oil that could penetrate the wet electrostatic precipitator is not present and therefore there is no risk of an oil fire due to contamination.

Star tube cooler

Gas coolers in the form of star tube coolers have been manufactured at JL Goslar for decades. Such coolers are components of gas purification plants for metallurgical waste gases and are required for cooling process gases, e.g. in the production of sulphuric acid, in order to remove excess water from the gas and produce sulphuric acid in the desired concentration.

Star tube coolers are provided in the cooling water area either with homogeneous internal lead coating or with a corrosion-resistant internal coating. Star coolers are shell-and-tube condensers made of lead. Lead offers excellent corrosion resistance to the action of weak acids. To improve heat transfer, the lead tubes are extruded with internal fins. The lead pipes required for this purpose with a star-shaped inner profile are produced at JL Goslar on an extruder press. The number of star tubes in the star tube coolers and the overall height of the star tube coolers can vary. This means they can be adapted to the amount of gas to be cooled. After production, the star tube coolers are subjected to a final pressure test.

The experience of our customers proves the high efficiency, reliability and durability of these star tube coolers.

At the end of their life cycle, complete recyclability of the materials used is ensured and is another good example of the sustainability of lead as a material.